C. The diver operation

When the water is not deep, the

valve of the submarine pipeline is usually equipped with a hand wheel. Divers can operate the valve of the submarine pipeline by the air diving method. In addition, for submarine valves with ROV interfaces, divers can also use special operating tools to operate the submarine valve by the saturation diving method if the condition permits.

Designs of ball valves of submarine pipelines

A. The main technical indicators

Service lives, design temperature, design pressure, forms of

ball valves, design standards, valve sizes, pressure ratings, materials of valve bodies, materials of valve balls, ROV interface levels, ROV interface modes, ROV interface standards and valve manufacturing grades should be taken into account when design ball valves. In addition, we should also pay attention to forms of valve bases, testing scopes and contents from the third party as well as high-pressure tank testing of valves and actuators. There should be a technical clarification between the buyer and the supplier, and the buyer needs to know technical details so as to prevent unnecessary modification of the contract.

B. Connection ends

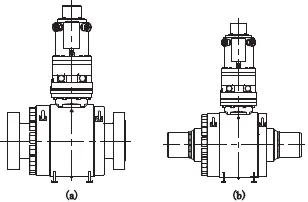

Connection ends of ball valves include flanged connection ends and butt welded connection ends two kinds.

(a)Flanged ends (b)Butt welded ends

Different connection ends of ball valves of submarine pipelines

Butt welded ends adopted for ball valves can improve reliability of the pipeline system, which can reduce the potential leakage source of

ball valves when flanged ends are adopted for ball valves. Adopting butt welded ends for ball valves doesn't have an impact on operation, dead weights and prices of ball valves except replacing and maintaining ball valves. Reliability and maintainability of ball valves should be taken into account when it comes to design of undersea oil and gas production systems. Given these factors, welding ends should be adopted for ball valves.

C. Sealing forms

Besides bearing inner pressure of media in deep water conditions, ball valves also bear hydrostatic pressure. Two different seals are often set between the valve body and the environment so as to prevent leakage of media or seawater getting into the valve body, and the metal seal is the main seal. Sealing surfaces of valve seats include a form of a single piston effect (SPE)and a form of a double piston effect(DPE) two kinds.

The principle of SPE is that there is a sealing area difference between the valve cavity and the upstream sealing surface. When pressure of the valve cavity increases to a certain value, the pressure difference between the valve cavity and the upstream is greater than the initial pressure of the spring, the valve seat will push the valve body to make pressure of the valve cavity release upstream. The principle of DPE is that there is a sealing area difference between the seat downstream and upstream. When inner pressure of the valve cavity increases, the valve seat will push the valve body to obtain double sealing of valves under effects of pressure difference and the initial sealing pressure of the spring. Generally, SPE plus DPE sealing should be adopted for ball valves. We often select SPE as the upstream sealing surface of valves in order to realize functions of automatic upstream releases when the valve cavity is overpressured.